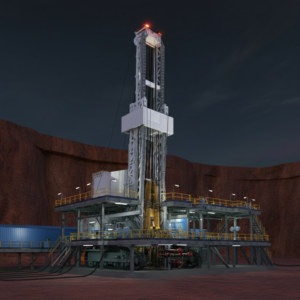

Introduction to Planta Fluidos De Perforación en Punata Camacho Edo. Zulia

The oil and gas industry depends on one critical component to enhance the efficiency of every single drilling operation: “ Planta Fluidos De Perforación en Punata Camacho Edo. Zulia” or drilling fluids. From cooling down drilling tools to stabilizing boreholes, these fluids play an integral part in the entire process. In this blog, let us focus on the application of drilling fluids in Punata Camacho, Edo. Zulia, a place which is the heart of oil and gas activities in Venezuela.

Modern considerations for safety with fluid usage, innovations and environmental trends will be discussed later in the blog. Whatever your association to the industry or oil and gas exploration is, this guide provides an understanding on the importance of performance, security, and drilling fluid sustainability relevance.

Defining Drilling Fluids and their Significance

“Drilling Fluids” can be comprehensively defined as prepared liquid mixtures to perform multiple tasks during the drilling work.Drilling fluids serve to control the pressure in the well, maintain the stability of the borehole, lift drill cuttings, and provide the necessary cooling and lubrication to the rotating parts.”planta fluidos de perforación en punata camacho edo. zulia

Effective selection and management of fluids impacts the efficiency of any drilling operation, while also mitigating complications. For example, improper fluid selection can lead to blowouts or wellbore instability.

In oil rich regions such as Edo. Zulia, which is of great importance to Venezuela’s energy sector, the significance of the oil drilling fluids in productive and safe operations cannot be underscored.

Exploring Planta Fluidos De Perforación en Punata Camacho Edo. Zulia

Located in the very center of Venezuelan Oil production, Punata Camacho in Edo. Zulia is a long standing heritage of petroleum extraction. Recognized globally for it’s rich hydrocarbons, this region is not only significant for the country but also for the world’s economy.

Geologically, the region presents a mixed bag of opportunities and challenges. Its complex formations come with advanced drilling challenges and require high quality drilling fluids worth the cost to achieve successful oil recovery. Companies in Planta Fluidos De Perforación en Punata Camacho Edo. Zulia often face unique challenges like strict environmental regulations paired with rigorous operational standards.

Types of Drilling Fluids Used in planta fluidos de perforación en punata camacho edo. zulia

Across the oilfields of Planta Fluidos De Perforación en Punata Camacho Edo. Zulia a range of drilling fluids are available, each with specific distinctive advantages that cater to particular operational requirements.

1. Water-Based Drilling Fluids (WBM)

Water-based fluids represent the simplest and the most common type of drilling fluids. A WBM consists of water together with additives such as bentonite (clay) and barite to increase viscosity and density. WBMs are cheaper and are less harmful to the environment than other options. This is the reason they are used frequently during operations in Edo. Zulia.

2. Oil-Based Drilling Fluids (OBM)

Oil-based fluids excel in challenging drilling conditions as they provide effective lubrication and stability at high temperatures and pressures. Because of their effectiveness, OBMs are also very restricted due to their high environmental impact from disposal and contamination.

3. Synthetic-Based Drilling Fluids (SBM)

Being a hybrid solution, they incorporate the benefits of OBMs while decreasing the environmental footprint. These are currently being adopted in areas like planta fluidos de perforación en punata camacho edo. zulia where operational demands are high but so is the importance of environmental sustainability.

4. Compressed Air and Foam-Based Fluids

These fluids are less popular but serve a purpose in limited scenarios where the priority is minimal damage to the reservoir. They are commonly used for underbalanced drilling in unconventional formations.

Environmental Issues and Compliance

Inevitable environmental consequences of drilling within the region make compliance with laws and regulations Planta Fluidos De Perforación en Punata Camacho Edo. Zulia important operational feature. The introduction and discharge of drilling fluids into the ecosystem is controlled by strict policies aimed at protecting groundwater sources, reducing waste, and contamination soil.

Contemporary ecological issues comprise the following:

The efficient disposal of oil-based drilling mud cuttings.

Preventing leakages or uncontrolled spills during work over operational sites.

The addition of novel additives which are biodegradable or non-toxic. While reducing ecological harm to the world.

Some businesses in the region have adopted more sustainable practices like recycling and reusing spent drilling muds, or using less toxic synthetic-based fluids.

Illustrations from Planta Fluidos De Perforación en Punata Camacho Edo. Zulia

Example 1 – New Borehole Stabilization

One of the oil companies in Punata Camacho recently begun using deep-water SBMs and was able to stabilize boreholes in complex geological formations, reducing costs by 15% and downtime.

Example 2 – Replacement with Green Fluids

Over the most recent five-year period, an initiative aimed at replacing oil-based muds with water-based, is expected to yield a drastic decrease in hazardous waste over time.

Tackling Problems in Drilling Fluid Administration

Fluid management in Planta Fluidos De Perforación en Punata Camacho Edo. Zulia presents unique problems for operational personnel. Some of the most frequent issues are:

Expensive: The operational cost is elevated with the use of SBMs because advanced fluids are (planta fluidos de perforación en punata camacho edo. zulia) more costly than traditional alternatives.

Waste Management: The environmental destruction caused by waste fluids during drilling operations needs to be managed efficiently.

Constant Adjustment: For each well, fluid formulations have to be adjusted frequently to match the geological characteristics and for optimal performance.

Innovative Solutions

Overhead can be reduced along with waste with better recycling programs, fluid reuse, and enhanced formulations.

Research and Development: Development of multifunctional additives is a prominent trend attributed to increased company investments into research. Polymers that enhance fluid properties across various scenarios are prototypes of modern multi-purpose additives.

AI-Powered Optimization: With a reduction in per-performance fluid waste during AI-monitored AI-controlled real-time optimization fluid formulation, drilling fluid parameters are better maintained through AI optimized real-time monitoring.

New Innovations and Trends

Revolutionary enhancements for the drilling fluid industry, which would greatly change the oil and gas operations in Edo Zulia, are predicted along with new operational trends such as advanced eco-friendly biochemicals.

Biodegradable synthetic and oil-based drilling fluids that perform with higher efficiency than their waxy counterparts during operations without having the drawbacks of harmful ecological impacts are anticipated.

Digital Twinning — Predicting fluid behavior in given conditions utilizing simulations of drilling operations.

Nanotechnology — Enhancement on thermal stability and viscosity control at the molecular level by integrating nanoparticles into drilling fluids.

Planta Fluidos De Perforación en Punata Camacho Edo. Zulia Region Sustainability Enhancement Project

Drilling fluids are crucial for the operational safety and environmental protection of the region. Oil fields of Punata Camacho Edo. Zulia still innovate and add value to the global petroleum industry.

Investment towards greener fluid technologies, managing waste appropriately, and implementing modern diitial technologies can address, meeting operational requirements alongside environmental obligations.

In the case you work at the oil and gas industry or are interested in the optimization of drilling fluids in planta fluidos de perforación en punata camacho edo. zulia, we encourage you to look further into maintaining performance and sustainability.

Frequently Asked Questions:

Q1. What is the significance of drilling fluids in oil operations?

Drilling fluids serve multiple functions that include borehole stabilization, well pressure control, cuttings removal, and the cooling of drilling tools, all of which ensure smooth operations.

Q2. What’s the difference between water based fluids and oil based fluids?

Oil-based fluids perform better in extreme high-pressure and temperature environments, whereas water-based fluids are eco-friendlier and have a lower cost.

Q3. What would be the challenges associated with the application of drilling fluids?

These include cost, waste disposal, environmental compliance, and the need to continually modify a well’s formulation in relation to its ever-changing conditions.

Q4. What actions are undertaken by different companies to minimize environmental impacts?

Fluid recycling, reformulation to less hazardous materials, and investment into materials that are readily biodegradable are some of the practices adopted within the region.