Introduction to Greasewatch 3

In the ever-evolving world of technology, keeping grease and machinery running smoothly is no small feat.

Enter Greasewatch 3, a game-changer in the maintenance industry that promises to revolutionize how we monitor lubrication systems.

Whether you’re managing a bustling kitchen or overseeing an industrial facility, understanding this innovative solution can save you time, money, and even headaches down the line.

But what exactly is Greasewatch 3? How does it work its magic? As we delve deeper into this complete guide, you’ll discover everything you need to know about harnessing its potential for your operations.

From impressive benefits to practical installation tips, let’s explore why Greasewatch 3 might just be your next best investment.

What is Greasewatch 3?

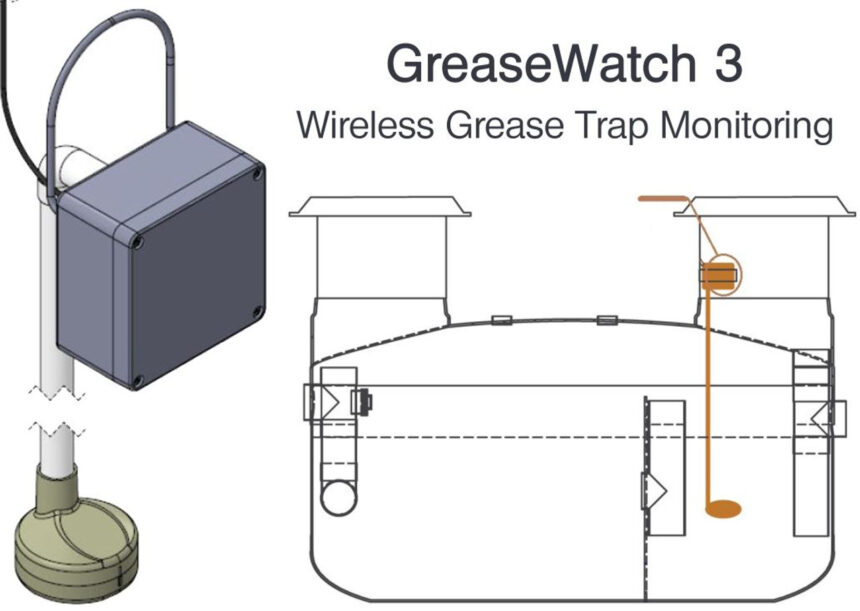

Greasewatch 3 is an advanced monitoring system designed to enhance grease management in commercial kitchens. It provides real-time insights into the grease levels within traps and interceptors, allowing businesses to stay compliant with local regulations.

Unlike traditional methods that rely on manual checks, Greasewatch 3 automates this process. This technology uses sensors to detect and measure grease accumulation without disrupting kitchen operations.

With its user-friendly interface, owners can easily access data through a mobile app or web portal. Alerts prompt timely maintenance actions before issues escalate.

This innovation not only improves operational efficiency but also promotes sustainability by minimizing waste disposal frequency. It’s a game-changer for restaurants aiming to streamline their kitchen operations while maintaining environmental standards.

The Benefits of Using Greasewatch 3

Greasewatch 3 offers several compelling advantages for businesses. One of the standout benefits is its ability to monitor grease levels in real-time. This feature helps prevent overflows, which can lead to costly damage and downtime.

Another significant advantage is improved efficiency. By automating grease management, staff can focus on other critical tasks. The system sends alerts when maintenance is needed, ensuring timely responses without constant manual checks.

Cost savings are also noteworthy. Regular monitoring reduces excess waste and minimizes service calls, resulting in lower operational expenses.

Moreover, Greasewatch 3 promotes environmental responsibility by minimizing spills and leaks into local waterways. Businesses adopting this technology contribute positively to sustainability efforts while maintaining compliance with regulations.

User-friendly interfaces make it easy for anyone to operate the system effectively without extensive training or technical knowledge.

How Greasewatch 3 Works

Greasewatch 3 operates on advanced sensor technology that continuously monitors grease levels in kitchen equipment. It provides real-time data, allowing users to track buildup without manual checks.

The system utilizes a cloud-based platform for seamless data access. Users can view statistics and receive alerts through a mobile app or desktop interface. This connectivity ensures quick responses to any changes in grease status.

Moreover, Greasewatch 3 is designed with easy installation in mind. Its sensors are strategically placed to gather accurate readings without disrupting daily operations.

Maintenance is straightforward, requiring minimal intervention once set up. Regular software updates enhance functionality and security, keeping the system efficient over time.

This proactive approach helps kitchens maintain optimal hygiene standards while reducing costs associated with cleaning and maintenance services.

Installation and Maintenance of Greasewatch 3

Installing Greasewatch 3 is straightforward, designed for ease and efficiency. The process typically starts with selecting a suitable location that offers optimal sensor performance. Once positioned, users simply mount the device using standard tools.

Connecting it to your existing system is equally simple. Most models feature plug-and-play capabilities, allowing for quick integration without extensive rewiring.

Maintenance is minimal but crucial for consistent performance. Regular checks ensure sensors remain clean and unobstructed by grease buildup or debris. Calibration should be performed periodically to maintain accuracy.

User-friendly dashboards provide real-time data insights and alerts regarding system status. This proactive approach helps in identifying any potential issues before they escalate into costly problems.

Staying on top of updates from the manufacturer ensures you benefit from the latest features and improvements, enhancing overall functionality over time.

Cost Comparison with Traditional Methods

When evaluating greasewatch 3, it’s essential to consider its cost-effectiveness compared to traditional methods. Traditional systems often rely on manual monitoring and regular maintenance checks, which can be both time-consuming and labor-intensive.

Greasewatch 3 automates these processes, significantly reducing the need for human intervention. This automation not only saves time but also minimizes errors associated with manual data entry.

Moreover, traditional systems may require costly components or frequent replacements due to wear and tear. Greasewatch 3 is designed with durability in mind, leading to lower long-term costs.

Another financial benefit lies in energy savings. By optimizing grease usage through real-time monitoring, businesses can reduce waste and improve operational efficiency—translating directly into lower expenses over time.

Investing in greasewatch 3 could yield significant returns when contrasting it against outdated practices that drain resources without delivering reliable results.

Real-Life Examples of Successful Implementation

Businesses across various industries have successfully integrated Greasewatch 3 into their operations. A restaurant in Chicago reported a significant reduction in grease-related issues after adopting the system. They experienced fewer plumbing emergencies and lower maintenance costs.

Another example comes from a large hotel chain that installed Greasewatch 3 in its kitchen facilities. The management noted improved compliance with local regulations, leading to a smoother inspection process. Staff members also found it easier to monitor grease levels, ensuring they maintained optimal performance.

A food processing plant implemented Greasewatch 3 and achieved remarkable results as well. By utilizing real-time data, the facility reduced waste disposal frequency while enhancing overall efficiency. Employees felt empowered by having immediate access to crucial information about their systems.

These success stories illustrate how versatile and effective Greasewatch 3 can be when applied thoughtfully within different operational contexts.

Common Misconceptions about Greasewatch 3

Many people believe that Greasewatch 3 is only for large industrial kitchens. However, this innovative tool can be beneficial for businesses of all sizes, including small restaurants and food trucks.

Another misconception is that using Greasewatch 3 requires extensive technical knowledge. In reality, the system is user-friendly and designed to be easily understood by anyone on staff.

Some think it’s an expensive investment with limited return. But when you factor in savings from reduced maintenance costs and improved efficiency, the long-term benefits far outweigh the initial expenditure.

Additionally, many assume that grease monitoring is complicated and time-consuming. Greasewatch 3 automates much of this process, significantly reducing manual labor while providing real-time insights into grease levels.

These misconceptions can prevent potential users from reaping the advantages of modern technology in their operations. It’s essential to break down these barriers for a clearer understanding of what Greasewatch 3 truly offers.

Future Developments and Updates

The future of Greasewatch 3 is bright, with continuous innovations on the horizon. Developers are committed to enhancing its functionality, ensuring it stays ahead of industry needs.

One exciting prospect involves integrating advanced AI algorithms. These enhancements could allow for more precise monitoring and predictive analytics. Users would benefit from real-time insights that anticipate grease buildup before it becomes a major issue.

Furthermore, plans are in place to expand compatibility with various kitchen equipment. This means even more establishments can leverage the power of Greasewatch 3 without overhauling their existing systems.

Regular updates will also focus on user experience improvements. Simplifying interfaces and adding features based on customer feedback fosters better engagement.

As technology evolves, so too does Greasewatch adaptability. Staying flexible ensures it meets future challenges head-on while providing sustainable solutions for businesses everywhere.

Conclusion:

Greasewatch offers an innovative solution for managing grease levels in various settings, particularly within the food service industry. As we’ve explored, it presents numerous benefits over traditional methods. With its user-friendly interface and advanced technology, Greasewatch 3 streamlines operations while ensuring compliance with health regulations.

The installation process is straightforward, making it accessible even for those unfamiliar with such systems. Regular maintenance keeps the system running smoothly without extensive effort or resources.

Comparing costs reveals that investing in Greasewatch can lead to long-term savings compared to conventional monitoring techniques. Many businesses have successfully integrated this tool into their operations, witnessing significant improvements in efficiency and cost-effectiveness.

Dispelling common misconceptions about Greasewatch highlights its reliability and ease of use. Anticipated future updates promise to enhance functionality further, keeping pace with evolving industry needs.

With these insights at your fingertips, embracing Greaswatch 3 could transform how you manage grease levels effectively. The shift towards modern solutions fosters a cleaner environment and promotes operational excellence across the board.