The Role and Importance of Desiccants in Modern Industry and Everyday Life

Desiccant are an essential yet often overlooked component in various industries and everyday applications.

These substances, which absorb moisture from their surroundings, play a critical role in preserving product quality, extending shelf life, and ensuring the efficiency of industrial processes. From the food industry to pharmaceuticals, electronics, and even household use, desiccants are indispensable.

This article explores the science behind desiccant, their types, applications, and their significance in modern life.

What Are Desiccants?

Desicca nts are hygroscopic substances that attract and hold water molecules from their environment, effectively reducing humidity levels. They work by either absorbing moisture through physical adsorption or chemical reactions. The primary purpose of desicc ants is to maintain a dry environment, preventing damage caused by excess moisture, such as mold growth, corrosion, or spoilage.

Types of Desiccants

There are several types of desicc ant, each with unique properties and applications. The most common ones include:

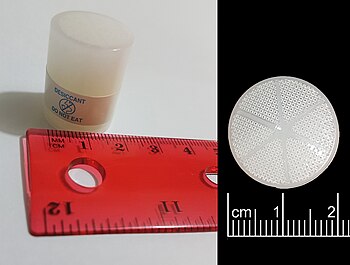

Silica Gel: Silica gel is one of the most widely used desiccan ts. It consists of porous granules of silicon dioxide and is highly effective at absorbing moisture. Silica gel is non-toxic, chemically inert, and can be regenerated by heating, making it a cost-effective choice for many applications. It is commonly found in small packets in packaging for electronics, leather goods, and food products.

Clay Desiccants: Clay de siccants, often made from montmorillonite clay, are another popular option. They are inexpensive, environmentally friendly, and effective at moderate humidity levels. Clay desiccant are commonly used in shipping containers, packaging, and industrial applications.

Molecular Sieves: Molecular sieves are synthetic zeolites with uniform pores that selectively adsorb molecules based on size. They are highly effective at removing water vapor and other gases, making them ideal for applications requiring extremely low humidity levels, such as in the pharmaceutical and petrochemical industries.

Calcium Oxide: Also known as quicklime, calcium oxide is a chemical desiccants that reacts with water to form calcium hydroxide. It is highly effective but less commonly used due to its reactive nature and potential hazards. It is typically used in industrial settings.

Calcium Chloride: Calcium chloride is a highly effective desi ccants that can absorb large amounts of water. It is often used in dehumidifiers and industrial drying processes. However, it can dissolve in the absorbed water, making it unsuitable for some applications.

Activated Alumina: Activated alumina is a porous form of aluminum oxide that is highly effective at adsorbing moisture. It is commonly used in compressed air and gas drying systems, as well as in the pharmaceutical industry.

Applications of Desiccants

Desicca nts are used in a wide range of industries and applications, including:

Food Industry: Moisture control is critical in the food industry to prevent spoilage, mold growth, and loss of texture. Desi ccants are used in packaging for dried foods, snacks, and spices to maintain freshness and extend shelf life. They are also used in the storage of grains and other agricultural products.

Pharmaceuticals: In the pharmaceutical industry, moisture can degrade the efficacy of drugs and lead to contamination. Desi ccant are used in packaging for tablets, capsules, and other medications to ensure stability and prolong shelf life. Molecular sieves and silica gel are commonly used in this sector.

Electronics: Excess moisture can cause corrosion, short circuits, and other damage to electronic components. Desicc ants are used in the packaging and storage of electronic devices, circuit boards, and semiconductors to protect them from humidity-related damage.

Shipping and Storage: Desi ccants are essential in the shipping and storage of goods, particularly in humid environments. They are used in shipping containers, packaging, and storage facilities to prevent moisture damage to products such as machinery, textiles, and paper goods.

Household Use: Desi ccants are commonly found in household products such as shoe boxes, closets, and storage containers to prevent mold and mildew. Silica gel packets are often included in packaging for leather goods, cameras, and other moisture-sensitive items.

Industrial Processes: Many industrial processes require dry environments to ensure efficiency and product quality. Desicc ants are used in the production of chemicals, plastics, and fuels, as well as in compressed air and gas drying systems.

Benefits of Using Desiccants

The use of desiccants offers numerous benefits, including:

Preservation of Product Quality: By controlling moisture levels, desiccants help preserve the quality and integrity of products, preventing spoilage, corrosion, and degradation.

Extended Shelf Life: Desic cants can significantly extend the shelf life of products by creating a dry environment that inhibits the growth of mold, bacteria, and other microorganisms.

Cost Savings: By preventing moisture-related damage, desiccan ts help reduce waste and lower costs associated with product returns, repairs, and replacements.

Improved Safety: In industries such as pharmaceuticals and electronics, desicc ants help ensure the safety and reliability of products by preventing contamination and damage.

Environmental Protection: Many desicc ants, such as silica gel and clay, are non-toxic and environmentally friendly. They can also be regenerated and reused, reducing waste and environmental impact.

Challenges and Considerations

While desiccants offer many benefits, there are also challenges and considerations to keep in mind:

Regeneration: Some desiccants, such as silica gel and molecular sieves, can be regenerated by heating, but this process requires energy and equipment. Other desiccants, such as calcium chloride, cannot be regenerated and must be replaced.

Compatibility: Not all desi ccants are suitable for every application. For example, calcium chloride is highly effective but can dissolve in water, making it unsuitable for some uses. It is important to choose the right desic cant for the specific application.

Safety: Some desiccants, such as calcium oxide, are highly reactive and can pose safety hazards if not handled properly. It is important to follow safety guidelines and use appropriate protective equipment when working with these materials.

Cost: While some desiccants, such as clay, are inexpensive, others, such as molecular sieves, can be more costly. The cost of desiccants must be weighed against the benefits they provide.

Future Trends in Desiccant Technology

As industries continue to evolve, so too does the technology behind desiccants. Some emerging trends include:

Smart Desiccants: Researchers are developing “smart” desiccants that can respond to changes in humidity levels, releasing or absorbing moisture as needed. These materials could offer more precise control over moisture levels and reduce the need for frequent replacement.

Biodegradable Desiccants: With growing concerns about environmental sustainability, there is increasing interest in developing biodegradable desiccants made from natural materials. These desiccants would offer the same moisture-absorbing properties while being more environmentally friendly.

Nanotechnology: Advances in nanotechnology are leading to the development of desiccants with enhanced properties, such as higher absorption capacity and faster regeneration times. These materials could revolutionize industries that rely on precise moisture control.

Integration with IoT: The integration of desiccants with Internet of Things (IoT) technology could enable real-time monitoring of humidity levels and automated control of desicca nt systems. This would improve efficiency and reduce the risk of moisture-related damage.

Conclusion

Desicca nts are a vital component in many industries and everyday applications, offering numerous benefits such as product preservation, extended shelf life, and cost savings. With a wide range of desic cants available, each with unique properties and applications, it is important to choose the right one for the specific use case. As technology continues to advance, we can expect to see even more innovative and efficient desicca nt solutions that meet the evolving needs of modern industry and everyday life.