Introduction to Acetatas

Acetatas are everywhere, yet many people don’t even realize it.

From your favorite eyeglass frames to the vibrant textiles in your wardrobe, these versatile materials play a significant role in our daily lives.

But what exactly are acetates? How do they work, and why should we care?

This comprehensive guide will take you through everything you need to know about acetates—unpacking their uses, types, properties, and much more.

Whether you’re a curious consumer or someone involved in manufacturing and design, understanding acetatas can open up new avenues for creativity and practicality.

Let’s dive into the fascinating world of acetates!

What Are Acetatas Used For?

Acetatas are versatile compounds with a multitude of applications. They play a crucial role in various industries, from textiles to pharmaceuticals.

In the fashion world, acetates are often used to create fabrics that mimic silk. This gives garments an elegant appearance while being more affordable than natural fibers.

The food industry also utilizes acetates for packaging. Their protective qualities help maintain freshness and extend shelf life, making them indispensable for manufacturers.

Moreover, in the realm of personal care products, acetates serve as stabilizers and emulsifiers. These properties enhance product performance and improve texture.

In laboratories, they act as solvents or intermediaries in chemical reactions. Their ability to dissolve other substances makes them essential for research and development.

From eyewear frames to photographic films, the uses of acetates are wide-ranging and innovative. Each application showcases their unique attributes effectively.

Types of Acetatas

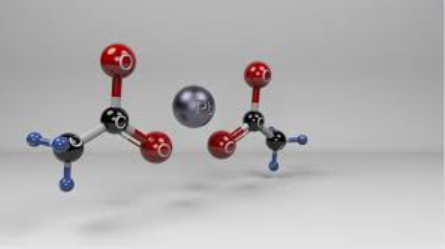

Acetatas come in various types, each tailored for specific applications. The two primary categories are cellulose acetates and synthetic acetates.

Cellulose acetate is derived from natural sources like cotton or wood pulp. It’s commonly used in film production, as well as in the creation of textiles and fibers.

Synthetic acetatas, on the other hand, are produced through chemical processes. They tend to offer enhanced durability and flexibility. This makes them suitable for packaging materials and coatings.

There’s also a distinction based on their physical forms—such as sheets, films, or granules—which further broadens their applicability across different industries.

Understanding these types helps manufacturers choose the right acetate for their needs while ensuring optimal performance in diverse applications.

Properties and Benefits of Acetatas

Acetatas possess a range of impressive properties that make them versatile materials. They are lightweight, which contributes to their popularity in various applications. This characteristic is particularly advantageous in industries like fashion and eyewear.

Additionally, acetates exhibit excellent clarity and gloss. Their ability to mimic the appearance of natural materials makes them an attractive alternative for designers looking for sustainable options.

One standout benefit is their resistance to UV light. Acetate products can withstand prolonged exposure without degrading or losing color vibrancy.

Moreover, they are hypoallergenic, making acetatas suitable for sensitive skin types often found in jewelry and accessories.

Their flexibility allows for intricate designs while maintaining durability. This combination ensures that acetate items not only look great but also last longer under everyday use.

Common Applications of Acetates

Acetates find their way into various industries, showcasing versatility and functionality. In the fashion world, acetate fabric is celebrated for its silk-like feel. It drapes beautifully and holds dye well, making it a popular choice for clothing.

In the realm of photography, acetate sheets serve as transparent overlays or film bases. They protect images while enhancing clarity through their smooth surface.

The food industry also utilizes acetates extensively. They act as effective food wraps that preserve freshness without altering flavors.

Moreover, acetates are commonly used in crafting and stationery products. Their flexibility allows for creative designs in scrapbooking and card-making projects.

Pharmaceuticals use acetates to coat tablets or capsules. This helps with controlled release formulations, ensuring medications work effectively when consumed.

The Manufacturing Process of Acetates

The manufacturing process of acetates begins with cellulose or synthetic raw materials. These substances undergo a series of chemical reactions to produce acetic acid esters, which are the foundation of acetate production.

Next, purification is essential. The resulting mixture needs to be distilled and filtered to remove impurities. This ensures that only high-quality acetates reach the market.

Once purified, the acetate is often blended with plasticizers for various applications. This step enhances flexibility and durability, making it suitable for different products.

Granulation occurs. The liquid form solidifies into small pellets or sheets ready for processing in industries like textiles or packaging. Each stage plays a crucial role in creating the versatile material we recognize as acetates today.

Safety Precautions When Handling Acetates

Handling acetates requires caution to ensure safety. Always wear appropriate personal protective equipment (PPE), such as gloves and goggles, when working with these materials. This minimizes skin contact and protects your eyes from potential splashes.

Ensure you work in a well-ventilated area. Acetates can emit fumes that may be harmful if inhaled in large quantities. A fume hood is an excellent choice for those involved in laboratory settings.

Store acetates away from heat sources and direct sunlight to prevent degradation or unwanted reactions. Keep them sealed tightly in proper containers labeled clearly for easy identification.

If spills occur, clean them up immediately using absorbent materials designed for chemical spills. Dispose of waste according to local regulations to minimize environmental impact.

Always familiarize yourself with the specific Material Safety Data Sheets (MSDS) related to the type of acetate you are using, as they provide critical information on handling procedures and hazards associated with each product.

Environmental Impact of Acetates

Acetates, derived from natural sources like wood pulp or cotton, can have both positive and negative environmental impacts. Their biodegradability is a significant advantage. Unlike many synthetic materials, certain acetates break down more efficiently in the environment. This makes them a preferred choice for eco-conscious manufacturers.

However, the production process of acetates often involves chemicals that may harm ecosystems if not managed correctly. Wastewater generated during manufacturing can contain pollutants that affect local water bodies.

Another concern is related to sourcing raw materials sustainably. Deforestation for wood pulp poses risks to biodiversity and contributes to climate change. Responsible sourcing practices are crucial in mitigating these issues.

Consumers increasingly seek transparency about product origins and sustainability efforts. Brands committed to ethical practices can help reduce the carbon footprint associated with acetate production while promoting awareness of its advantages and disadvantages within various industries.

Alternatives to Acetates

When exploring alternatives to acetates, several materials come into play. One popular choice is polycarbonate. This synthetic polymer offers excellent durability and impact resistance.

Another option is cellulose acetate butyrate (CAB). It provides a gloss finish and improved weather resistance, making it suitable for outdoor applications.

For those seeking eco-friendliness, biodegradable plastics like PLA (polylactic acid) are gaining traction. Derived from renewable resources, they break down more easily than traditional plastics.

Natural fibers such as cotton or linen can also replace acetates in certain textile applications. These fabrics offer breathability and comfort while being less harmful to the environment.

Glass is an elegant alternative that doesn’t compromise on aesthetics or quality. While heavier than acetates, its recyclability makes it a sustainable choice for various products.

Conclusion

Acetates play a significant role in various industries and everyday products. Understanding their uses, types, and properties reveals just how integral they are to modern life. From fashion to pharmaceuticals, acetates impact many fields with their versatile nature.

The manufacturing process of acetates continues to evolve, embracing greener methods that minimize environmental footprints. Safety precautions remain essential for anyone handling these materials due to the potential risks involved.

As we become more conscious of our surroundings, exploring alternatives to traditional acetates is crucial. Innovations in material science may offer sustainable solutions without sacrificing quality or functionality.

With continued research and development, the future of acetates looks promising. Their adaptability ensures they will remain relevant while also adapting to meet new challenges in sustainability and safety standards.